I did this interview with Robbie Pierce back in 2020. I thought it fitting to publish it now to immortalize his voice so people could understand who he was from his own perspective. A leader, racer, builder, entrepreneur, and Off-Road Motorsports Hall of Fame Inductee, Robbie had a massive impact on off-road and racing culture globally.

I know some of your history, obviously, you started working in the business as a welder.

Yes. Started in 1981 over next to Autofab, a little small shop right next to McDonald’s called Autofab. We scan in transfer trucks and dump trucks and work on equipment.

And was that straight out of high school? Or what did you do?

No, I was like 22, 23 years old then. I had been working, just finished up, and went to Imperial Valley College, doing a weld tech program, which is down the Valley, and the reason I chose that was everybody, all the schools, trade schools, or community colleges in San Diego catered to NASSCO, and I didn’t really want to build ships for a living. They had a nice weld tech program, highly rated by the American Welders Society.

So, I would make the trip two or three times a week, and go down there. I’d gotten a job at a company in Oklahoma welding and machining, and they also had a small company called Main Truck Bodies, building small flat beds and things like that in the early eighties, when the gas crunch was so bad. The problem with this is that they ended up going out of business because the results of the gas crunch and the recession, there was no construction.

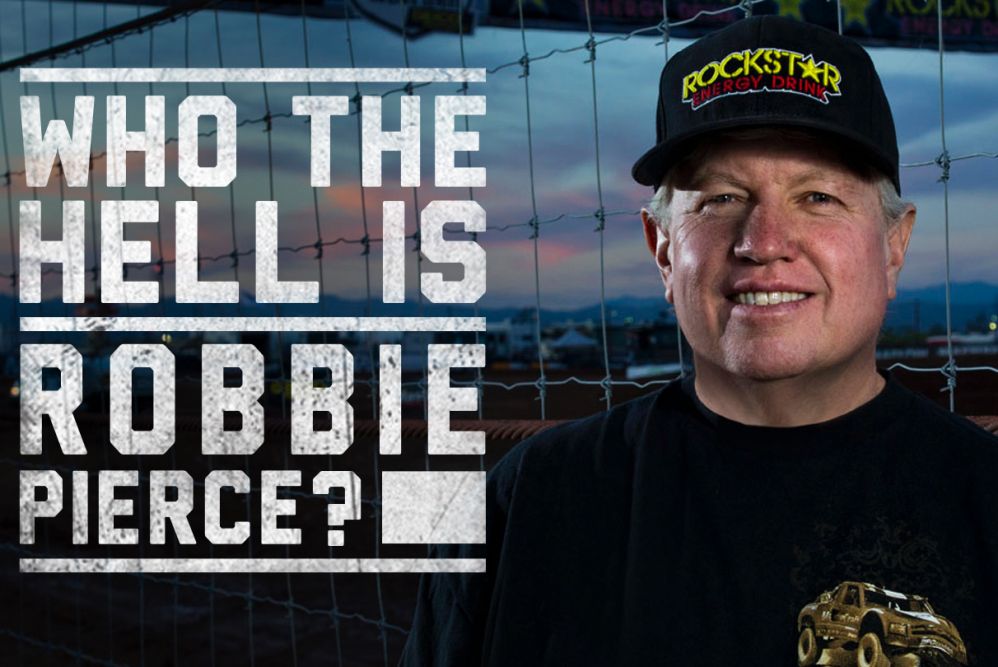

Robbie Pierce at Jimco Racing

I started in 1981, just a little 1200 square-foot weld shop with a chop saw and SD 200 Lincoln welder, and a vector torch. That’s how we started it. Then I, eventually, got out of that. I bought a TIG machine and the guy brought in some aerospace parts for me to weld up and found out that was a lot easier to do and a lot nicer to do sitting on my bench as opposed to crawling around out in 110-degree heat with a jet arc cutting skins off dump trucks.

I decided we wanted to do a little bit more aerospace welding, so that’s how the company evolved with doing aerospace, but in that, of being next to John over at Autofab … At the time, AutoFab was the hot bed of, and at least from what I saw, of off-road, right? They had some very talented guys there at the time. They had, you know, of course, it was John Ehmke, Cobb, Ted Kendall. There were some different, different people there. There’s been a lot of guys that have come out of that shop. Mark Newhan came out of that shop, but Steve came over one day and asked me if I was interested in TIG welding up their class 8 chassis. So, started doing a little bit of that. Not exactly my first time working on race cars, but I’d really enjoy that, but you have to follow the money and with the little weld shop that I had, the aerospace kind of grew, and did some stints working in the golf industry with titanium, I specialized in exotic metals.

When the golf industry went into titanium, they came knocking and I ended up setting up some different processes for most of the major golf club manufacturers, Cobra, Titleist, Calloway, all those guys. I was always doing different jobs, along with in that was from Autofab, and knowing John Perricone from Mastercraft. I started building their seat frames. They needed metal products, I built them before. Mastercraft asked John to build seat frames for them. He said, “No, but there’s a kid over next door that’d probably do it. So, that’s when I started building frames for a Mastercraft. I think it was about 1985 and built frames for Mastercraft up till 1999 when I ended up buying the company. Perri was wanting to do different things. So, one of the things I’ve learned in the golf business was that I really needed an exit strategy to have my own product. I was already building the frames, and it’s kind of one of the lies that you tell yourself, well, how hard can this be? Right? So, I already building the frames! Well, it was a lot harder than I thought, but that’s how we got started with MasterCraft.

Robbie Pierce throwing it sideways in his Jimco Trophy Truck

Nice, and you took Mastercraft from being what size company to a much larger company than original?

I always use numbers. When I first bought Mastercraft, I knew how many seat frames they were building because I was the one building all the frames. So, we do about 140, 160 seats a year. It was a very small company. They also did bags and things like that. When it got to its prime, it was probably doing 150 seats a day, six days a week. So that was a lot of that was military. Around 2005 or so, the military came knocking. Because I had some experience with aerospace, I knew their language and knew how to respond to them and we’re just in the right place at the right time. Right. So I guess you could say we’re lucky, but you know, it’s a, but we were in the right place, right time and just have the seat chosen for a new vehicle called the LSAC, the Low Signature Armor Cab, and within a few months, they were ramping up for that to go forward and everything.

So, as it turned out with their testing and our own internal testing with the suspension seats, they’ve mitigated energy for blast attenuation quite well. So, that was a nice attribute, besides it just being a seat, not only they were more comfortable than what they were normally having in militaries, but they also attenuated energy, so they were a safety factor for the soldiers. We ended up building seats for approximately 50,000 military vehicles up through 2012, 13ish, and to this day, Mastercraft still does probably, I don’t know, maybe a couple of thousand seats a year for the military.

Then that wasn’t enough? So you had to buy this company called Impact?

Well, in 2009/10 as you start to see the end of that military business start to drop off and you’ve built this infrastructure to support that, we had 100 people, two buildings to build those 150 seats a day, six days a week, plus restraints, plus all the other items that went along with that. So, you’ve got this infrastructure that you have to support and nobody wants to back out. So, I started looking for ways to fill that gap in revenue loss that we were going to see, and the opportunity came up to purchase Impact. I wasn’t looking for it. I was looking to diversify a little bit and started mass-marketing our own driver’s seats. So, I decided to kind of look at the NASCAR landscape a little bit and see what we could do. So, I was looking for something to do. We went to a NASCAR race in Pocono, Robbie Gordon was racing at the time, and we went to his trailer. I didn’t really want to go in, didn’t want to be that guy. Kelly insisted, we went in, Robbie wasn’t there, ran into PJ Jones and who happened to be good friends with Bill Simpson. Asked what are we doing there. We’re looking to expand the suit business, and he let us know that he was good friends with Bill, and Bill might be interested in selling Impact.

So, then a few weeks we were taking a trip to Indianapolis and met with Bill and put a deal together to help Impact. They were really struggling and we kind of took a look at, can we rehab this company? Can we change its image and brand and raise its quality of it? We thought we could, so I ended up making a deal with Bill to buy the company. Like, again, like everything else, the lies you tell yourself, how hard can this be? Right?

It took a good long four years before we finally started getting it turned around. We had a lot of product development to do: change the product, and raise the quality of the product. There were some really good products, but it’d just not been maintained very well. About 2014, that really started to turn around. I ended up having to spend about 10 months a year back there in Indianapolis and for somebody that was born and raised in San Diego, it was a little tough, not so much the weather, I just missed the offroad.

So, the opportunity came in 2017, we built a big enough name for ourselves. We’re just irritating enough to some of our competitors, that Sparco came along and wanted to purchase us, so we were able to put a deal together with them. So, the whole company, both Mastercraft and Impact, and allowed us to move back to San Diego.

Once we got here back to San Diego, I was kind of semi-retired. I knew that it wasn’t completely done. The opportunity, you know, just hanging around here and having Jimco be a block away, I ordered a new truck and going over there and checking on. I was helping Matt with the business and the opportunity came up for us to, he was looking to do something different with it, and it seemed like a nice fit for me. It got me back into doing some fabrication. It seemed like a fitting last chapter, so to speak, to my career. I always told Mike Julson, the honor of Jimco, that I always bled Jimco blue. So, I always felt like I owned part of it anyway because I’ve had two trucks over there for the last 10 years. So, it worked out pretty well.

You’re a creator by nature like you had kind of a pretty special relationship with Mike Julson and then that led to the purchase of Jimco. I even see it with you now. It’s like you’re always trying to crack the puzzle, right? Is that something that drives you?

Yeah, it is kind of a drive and I don’t know if it’s the, I think it’s a fear of failure, right? The challenge of it is something … I think when I’m all said and done at some point in time, the thing that I will miss is that I’ve never started from the ground up a brand. I took Mastercraft and I hope made it a little better. I took Impact and, hopefully, drove a little while and made it a little better.

One of the best compliments I ever had was from Chuck Davis at Simpson and he said, “Hey, you took a company that was going to go out of business and you made some better products and probably saved some lives.” So, I thought that was a pretty nice compliment. And Jimco, the same deal, I think it, at the time, needed a little bit of breath of fresh air into it, right? No matter what you do after a while for long enough, it wears you down. So, just a new somebody looking at it from a different perspective. So, it’s been a challenge, and again, back to the line to tell you, so how hard can this be? We’re going to build a few race trucks and cars, and we’re going to do a little racing.

Well, pretty soon it’s you’re busy and your stuff is getting kind of set aside because you got to take care of this customer’s products first, customer’s vehicles first. So, you’re not doing the amount of racing that you wanted to do, but then there’s also the challenge of making it a real business and making it make money and making it thrive, and molding it into what I wanted it to be.

Robbie Pierce premiering the Jimco dragon at Dodgers Stadium

Right, and what of your future plans do you want to discuss?

Well, Jimco has so much unlimited potential. You’ve brought certain things up. There are all kinds of things that it can do. I hope to just drive it for a little while. I hope that I can just push it into the next 40 years. I don’t want to, I certainly won’t be around for that to happen, but if over the next five, 10 years, I can position it to where somebody can come along and take it into the next 40 years, I think that would be good. I hope I leave it in a better position than it was when I bought it. It’s what I hope I’ve done with Mastercraft and Impact.

What I love about off-road is that it’s one of the last types of motorsport that hasn’t been completely overtaken by corporate America, right? So, it’s still a hobbyist that are filled with passion for the sport, and you have to have that, all the builders that I know, all our competitors are very passionate about what we do. None of us are sitting in big, giant mansions up on a hill someplace. Right? So, everybody that does this is … We’re still all partners, John from TSCO called me today to ask me a question, right? I don’t hesitate to call Rick Geiser if I have a question. Another one of the compliments is that we’ve got to the Herbst who build trucks and Masons’ who build trucks calling us to buy some of the safety products that we do because I still have that reputation. So, it’s still a family, and that’s what I really enjoy about it.

Just like impact was or anything else, I want to make the product the best that it can be. Be proud to put the Jimco name on it. At least the Jimco by Robbie, you know? I think just like all the other two companies, I’m starting with a really, really good brand, and so just looking for it to move that forward and make it a little better.

Robbie Pierce at Jimco Racing

Do you want to talk about the four-wheel drive truck?

Sure, yeah. Jimco’s first and foremost, I hate to say the word buggy because Mike Julson will kick me in the shin because he says $500,000 cars shouldn’t be called buggy. It’s a race car. It’s an open-wheel, off-road race car, and it seems kind of silly to call them buggies. First and foremost, that’s what we do. We build cars and Jimco has always been at the forefront of building the best Class 1 Cars, there are other manufacturers, but Jimco has been the leader, I think we’re 22 chassis championship manufacturer of the year awards.

Mafuzar Motorsports Jimco Class 1 Hammerhead

Jimco also started building trucks. That’s the premier class now and they started building trucks back in 2005. I happened on the first one that was ever built. So, that evolution has kept on going, but when I first bought Jimco, just designing a new class one car, the hammerhead, which we’re really excited about, there’s six of them out there now in really good capable hands with Cody Parkhouse and the Wilson team. Those are top-notch teams. We’re really still excited about the potential of those cars. We’ve got a new customer that just took delivery of his back in March. Unfortunately, it hasn’t been able to race yet because of the COVID situation. We’re excited too, hopefully, to get him out for the Baja 500, but back to the trucks …The evolution has been towards this all-wheel drive technology and it’s not necessarily a new technology, but it’s come around again and our competitor, Mason, has had some good luck with it. I don’t think, personally, I don’t think that it’s made a big leap forward that it should, and then maybe that will come, but we have a new one that we’re manufacturing. We’re hoping to have it ready for Baja 1000, the COVID thing, maybe, might’ve pushed that back a little bit, but yeah, we’ll have a Jimco that we’ll drive here by the end of the year.

Pingback: therapist website design

Pingback: Online medicatie kopen zonder recept bij het beste Benu apotheek alternatief in Amsterdam Rotterdam Utrecht Den Haag Eindhoven Groningen Tilburg Almere Breda Nijmegen Noord-Holland Zuid-Holland Noord-Brabant Limburg Zeeland Online medicatie kopen zonder r

Pingback: link

Pingback: หวยออนไลน์ LSM99

Pingback: https://api.gugui.info/index.php?url=https://casino-spin.de/

Pingback: สล็อตเว็บตรง

Pingback: buy peruvian flake cocaine USA

Pingback: packman live resin cartridges

Pingback: nagaway สล็อต